The unfathomed longevity of the famous 100 series fixed blades

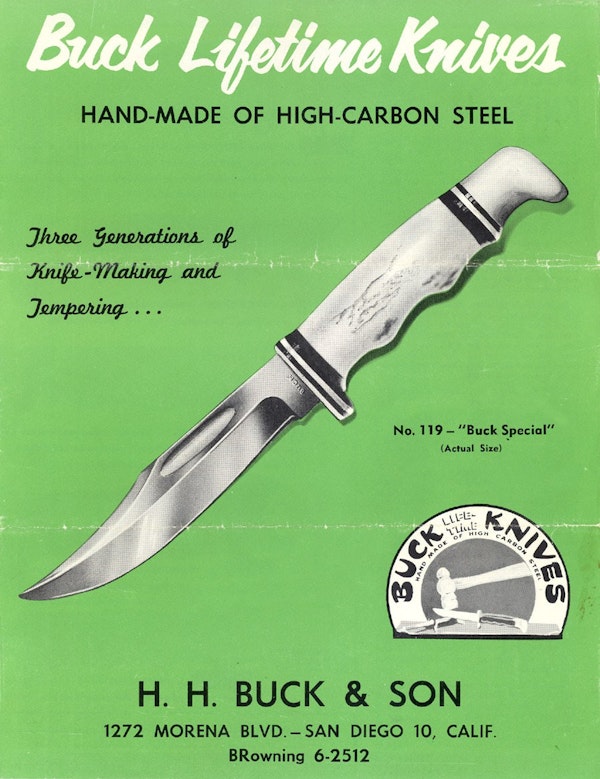

Built with premium steel, upgraded handle materials and heat treated to an exact preciseness, one could say Buck’s 100 series of fixed blade knives have come a long way from their initial launch in 1961. It could also be argued that the line is essentially the same, timeless designs ringing true to the old ad campaigns from the 1960s advertising “Buck Lifetime Knives.”

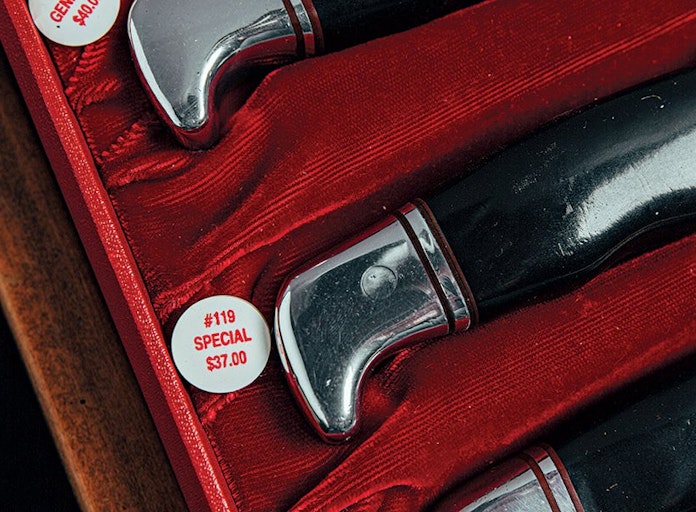

Still hand edged and hand sharpened, the newest Pro 100 Series feature familiar models in S35VN, a modern day super steel, and canvas Micarta handles. Impressive as the Pro’s may be, the classics still hold the top selling position in Buck’s lineup. Their black phenolic handles and deep clip point blade profile are unmistakable and undeniably iconic. In fact, one of the most famous and recognizable knives of all time, the 119 Special, dates back to WWII.

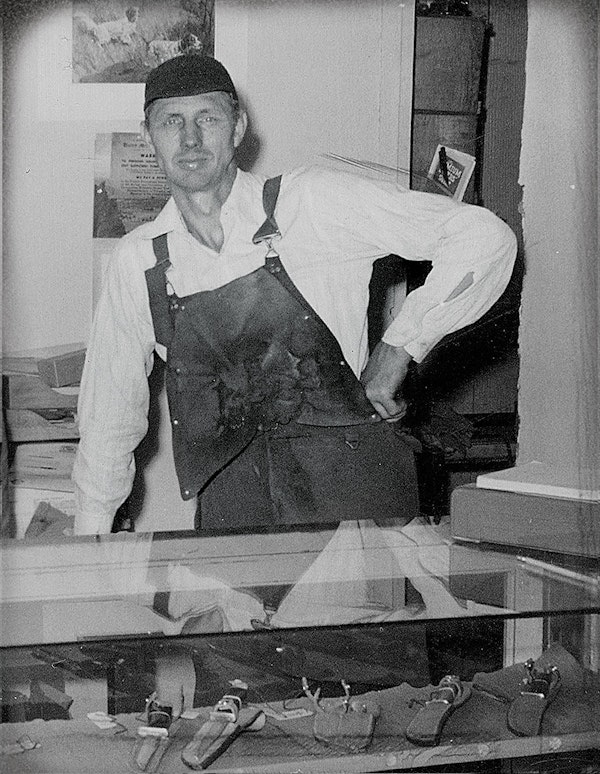

It’s hard to imagine this line got its start in the 1940’s when Buck Knives founder, Hoyt Buck, was tempering file blades and molding Plexiglas handles to donate knives to our troops during WWII. Dialing in his tempering process, he described treating steel as “heating it to the color of butter, just before butter melts.” It’s also been told that Hoyt knew by a certain smell the steel put off that it was hot enough.

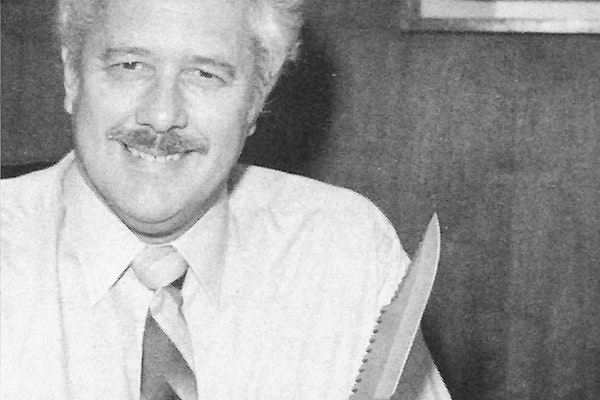

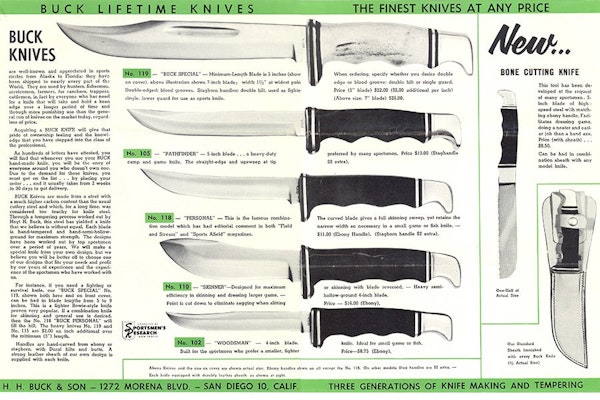

Having his processes in place and teaching his son Al Buck the business, they set off promoting their “Lifetime Knives,” in early ads and door-to-door demos by cutting a bolt in half with their fixed blades. This was quite effective in convincing people of the blade sharpness and toughness.

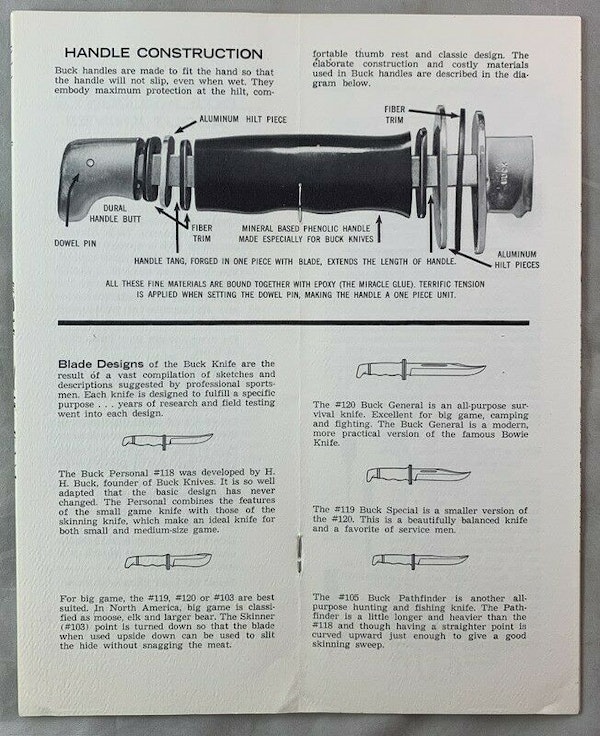

It wasn’t till the 1960s that the knives took hold in the familiar form we recognize as the classic fixed blades, the 102 Buck Woodsman, 103 Skinner, 105 Pathfinder, 118 Personal, 119 Special and 120 General. Carrying on the business after Hoyt’s passing in 1949, it was in 1961 that Buck Knives debuted these models in 440C steel and black phenolic handles, bearing only the word BUCK stamped in the blade. At this time the handle spacers were leather and aluminum, in most cases using two leather spacers and one aluminum on each handle end. A rare find indeed is a version that used three leather and two aluminum spacers on the pommel end. It’s theorized this was done to accommodate shorter handle material cuts yielding a bit of additional material that wasn’t to be wasted. These models were assembled via barrel-nut construction, where a threaded bolt was brazed to the end of the steel tang and the hollow handle components were slid onto the tang, stacked in order with the pommel designed to screw onto the bolt and firmly tightened with an aluminum barrel-nut plug.

Several refinements and material changes have occurred over the years, but the line is essentially the same in function and aesthetics. Barrel-nut assembly was replaced with pinned tangs to ensure the handle wouldn’t loosen, a process Buck still uses to build these models today. Pinned tang is where the entire handle component is tightly compressed and then a hole is drilled into the pommel, through the steel tang. A rivet is then inserted, sanded and polished, nearly undetectable, but can be seen in certain light. Around 1963 the leather spacers were replaced with bone hard fiber spacers, and again in 1969 Buck changed the material to Micarta and began utilizing just one spacer on each handle end, just as the knives are produced now.

Buck Knives began stamping BUCK USA on the blades in 1967 to allow them to export into Canada as country of origin was required on the product. Also in 1967, a small dot was stamped next to the K in BUCK on the blades. This dot was to mark the change from forged to machined blades. 440C was used until 1981 when Buck switched to 425 modified steel, lasting another 11 years. 1992 marks the final steel choice for this line, using the Bos heat treated 420HC, which is found on many Buck models. Over the decades, Buck has maintained dual versions and special offerings of the 100 family, often presenting an alternate option to the classic phenolic models for differing performance and aesthetic tastes. Ranging from the earliest white melamine, to the rich Cocobolo versions, and innumerable limited editions, the constant has been the faith people have in the 100 series. Al Buck couldn’t have known at the time that his “lifetime knives” would really be in his product line for a lifetime, remaining as best sellers some 60+ years later.

When talking with CJ Buck, he attributes the line’s success to his grandfather Al’s faith and pragmatism. “My grandfather was a man of great faith, yet at the same time was extremely pragmatic. He would have nothing to do with gimmicks, bells or whistles that did not add functionality. Our brand became synonymous with clean functional lines and materials. I think it was why the early fixed blades have this unfathomed longevity, they have always performed.”

Knives from the 100 series were built for life, an everlasting design your father, grandfather and possibly his father used in their time. They are the knives that worked then, certainly work now, and maintain a heritage and classic ethos few other items enjoy, a status as “lifetime knives”.