Paul Farner’s grandfather was stationed for military service with Al Buck. When Farner and his family moved to El Cajon, CA, they rekindled the friendship with the Buck family. For Farner’s 12th birthday, Chuck Buck gave him his first Buck knife, a 301 Stockman. The family bond within that knife business stayed with Farner, and he cherished that first knife. Years later, Farner was working as a commercial carpenter. He even joined the union and received his journeymen certificate. As an amateur auto mechanic, as well, he worked on classics and built a few race cars. But when the economy slowed in the early 1990s, Farner had to pivot and learn a new trade.

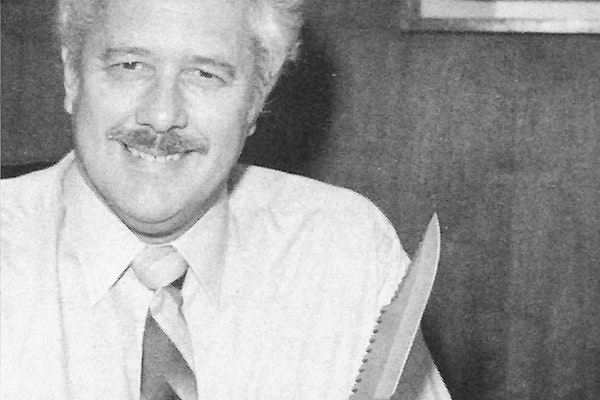

In 1994, Paul Farner went to work for Buck Knives. He started on the floor in assembly, like most new employees do. At the time, the legend of heat treat, Paul Bos, was single handedly running Buck’s in-house heat treatment facility. Farner didn’t mind the heat, having grown up with the higher temperatures of inland California. And Bos needed the help.

Farner began his training in the heat treatment of steel, and at Buck Knives, the company believes you cannot produce a quality knife without that process. There is a critical temperature of steel that makes it malleable and begins to change its chemical structure. Steel heated above this temperature enters what is called the austenite phase. During this phase, the grain quality of the steel changes.

Taking unrefined steel alloy through various heat treatment processes is the only way to make all the finished steel parts we use.

When hot steel is cooled and solid again, it cannot be used as is. Heat treated steel must be tempered before it can be used as a commercial material. Tempering is also heating steel, but this time below the critical temperature.

Tempering steel is a way to make hardened steel less brittle and change its durability to suit your needs. Each steel project may require a different heat level for tempering, but tempering never pushes steel back into the austenite phase.

Quenching is the industry term for rapidly cooling hot steel to make it hard again. Depending on the project, hot and malleable steel will be dipped in either water, oil, air, or even liquid nitrogen to cool. This brings the steel back to a solid state. The way steel is cooled will greatly affect its finished quality.

“You’re like a cook, they are certain recipes in heat treat,” Farner explains. He uses an oven that is over 50 feet long, which has four different temperature stages. The average temerature for most knife steels is around 1900 degrees fahrenheit. The quenching is done in a cyro freezer that can reach negative 220 degrees fahrenheit.

"People come to us for our reputation," Farner says. "Heat treatment is one of the most important steps in the process of making a Buck knife."