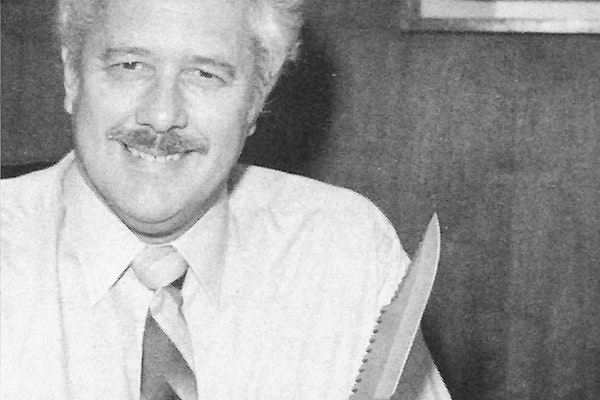

His whole family carries Buck Knives. Being from St. Maries, Idaho the fixed blade and folding hunters Buck makes are not only great tools, but necessary for Michael Mann to live. Hunting, fishing, and daily outdoor work were just a part of life when he was growing up. Mann developed a fascination with knives, steel, and building things from scrap at an early age. He made knives out of old chainsaw bars, and later, while in the military, he was the go-to knifemaker and sharpener for his squad. So, when he heard Buck Knives was relocating their headquarters and factory to Idaho, he couldn’t be more excited.

After his service in the military and work as private security, where he always carried a Buck, Mann got an opportunity to work for the company. He started on night shifts in prep, the fabrication department. A year later he was certified to run almost every machine, including all of the grinders, on the floor. This allowed Mann to become a trainer and move to the day shift, where he was a lead for the next two years.

Part of his military service required Mann to test various fuels for a myriad of applications, ensuring each vehicle, generator, or piece of machinery ran properly. This experience opened up the door at the Buck Knives Quality Assurance department. He couldn’t have been more well suited for his new role. “Everyone in that room has a background somewhere else in this building,” Mann explains. They work as a team, while individually bringing a specialty to the table.

That team acts as a central hub of information for all of the other departments if any questions arise. Quality Assurance identifies problems and solutions throughout every stage of the knifemaking process, turning over their findings to the engineering department for implementation. Testing ranges from blade sharpness, where a specific, abrasive paper is run over the blade consistently to gauge how long it will stay sharp, to a cycle test, pushing locking and folding mechanisms to the equivalency of use over 10 years. “We don’t want to know what it [knife] will do in everyday work, we want to know what it will do in the most extreme environments we can put it in,” Mann says.

Quality is important. Mann realizes Buck Knives, and its quality, existed long before him, and he uses that. It motivates him. “I don’t want to send out anything that is subpar because that would be discourteous and disrespectful to those who have come up behind me,” Mann sternly exudes. He is proud to work for such a recognizable brand, and he hears knife stories from strangers all the time. That legacy is also important. One day, when he is old and retired, people will still love and use knives he worked on 40 years ago. Those knives will mean something to those individuals. And it reminds Mann of the 110 his grandfather gave him, a knife bought in 1963, when that model was first released. That is the quality he strives for today.